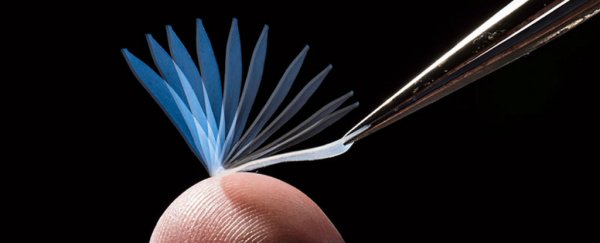

Scientists have developed a special heat-sensitive polymer that's capable of lifting 1,000 times its own weight and quickly contracting back to its original shape. The new material could eventually be used in everything from medical devices that work according to your body heat, to clothes that automatically shrink to provide a snug fit.

The fact that the heat of a human body is enough to get the polymer to react is what makes it such a potentially useful material. It can be programmed to retain a temporary shape before a heat trigger is used to return it to normal, lifting many times its own mass along the way. In the video below, you can see it in action, pulling toy trucks and lifting weights.

"Tuning the trigger temperature is only one part of the story," said one of the researchers behind the new polymer, Mitch Anthamatten from the University of Rochester. "We also engineered these materials to store [a] large amount of elastic energy, enabling them to perform more mechanical work during their shape recovery."

Crucial to the development of the new material - which its inventors are describing as "plastic with a brain, and some muscle" - is the way it controls the crystallisation that usually occurs when the polymer is cooled or stretched.

As the material is deformed, polymer chains are locally stretched to form crystallites, and small areas of polymer are aligned in the same direction. As the number of crystallites grows, the new shape becomes more stable, and it becomes more difficult for the plastic to revert back to its original form.

By using molecular liners that inhibit (but don't stop) this crystallisation process, the researchers were able to set a 'melting point' at which the shape change is triggered. The team adjusted the number and types of liners used, as well as experimenting with their distribution patterns through the polymer, in order to reach their end result.

The shape-shifting was only one target though. Anthamatten and his colleague Yuan Meng also wanted the material to perform some mechanical work during the transformation. So to do that, they engineered polymer networks that could store enough elastic energy to allow a piece of polymer the size of a shoelace to lift a can of soda.

"Our shape-memory polymer is like a rubber band that can lock itself into a new shape when stretched," says Anthamatten. "But a simple touch causes it to recoil back to its original shape. Nearly all applications of shape memory polymers will require that the material pushes or pulls on its surroundings. However, researchers seldom measure the amount of mechanical work that shape-memory polymers are actually performing."